What We Do

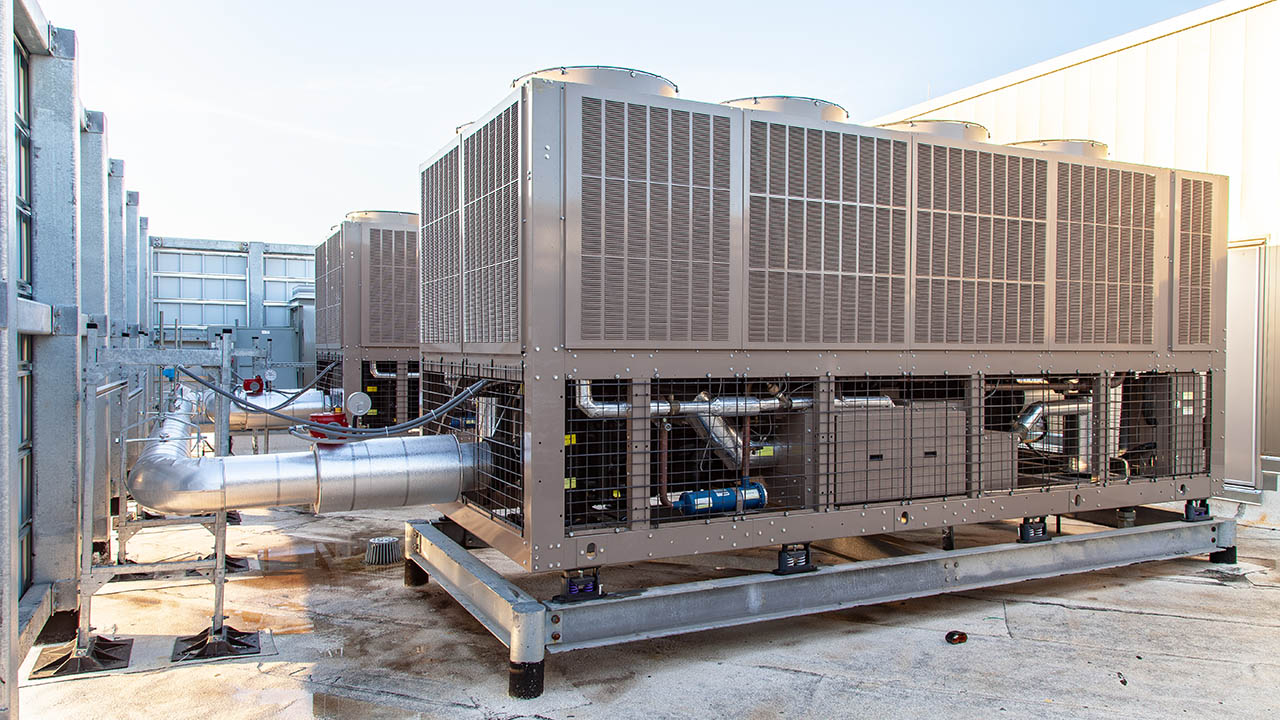

Mechanical

SkiHi Offers a complete mechanical solution for a broad range of institutional, commercial and industrial HVAC implementations. With more than 35 years of experience, you can count on SkiHi to deliver top-notch results.

Plumbing

From complex hospital projects to commercial kitchens and central energy plants with high-pressure industrial steam, SkiHi has the experience to tackle all of your plumbing needs.

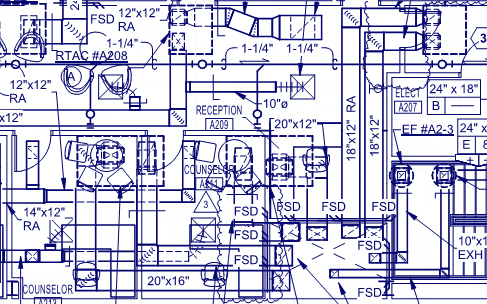

Detailing

Our capability to provide quality 3D BIM imagery and coordination drawings has allowed SkiHi to emerge as a leader in this segment of our industry. We have also added FARO laser scanning to our arsenal to provide a complete view of the project landscape before the first foot of pipe is installed.

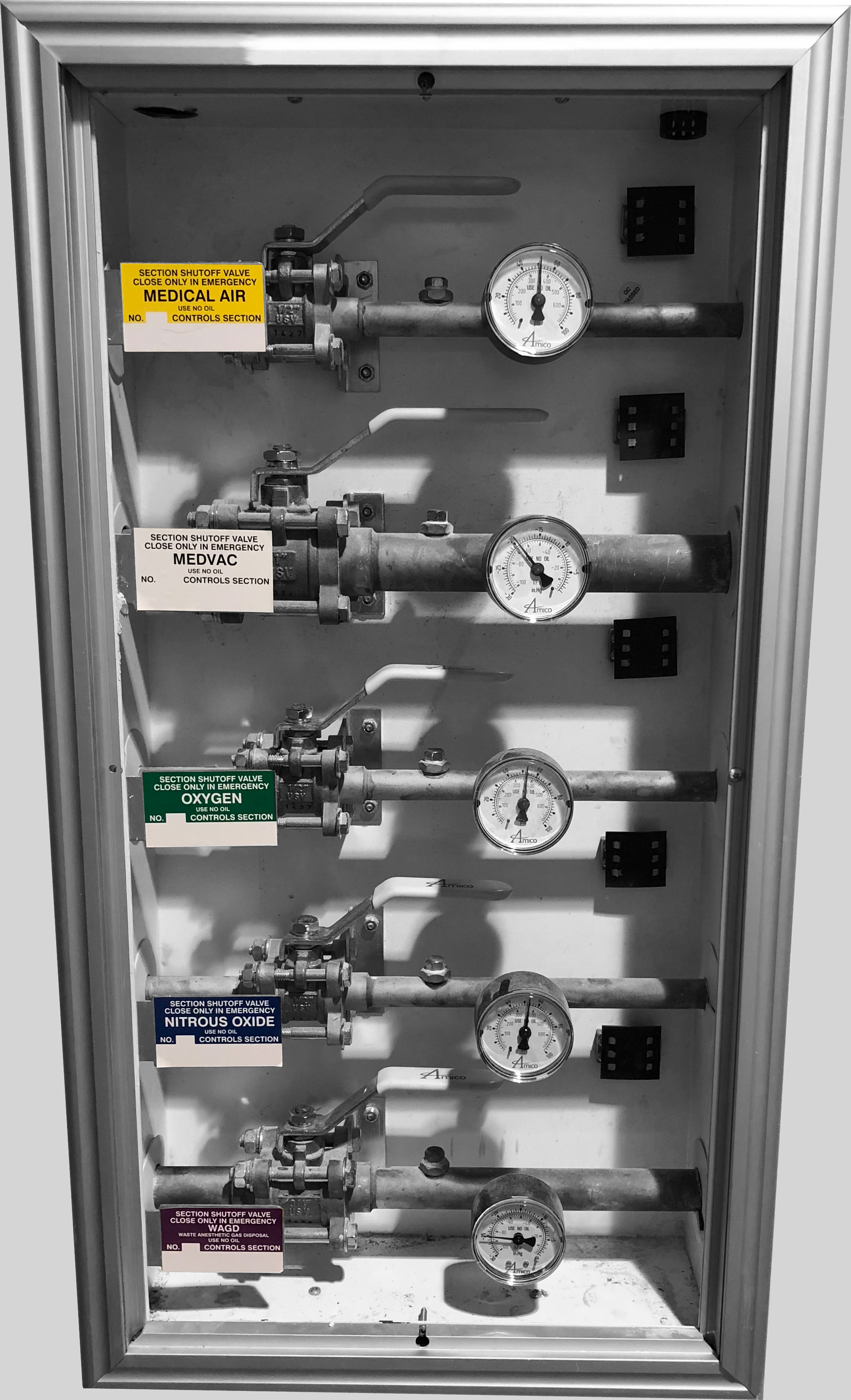

Medical Gas

A large percentage of our work is building hospitals, medical offices and laboratories. SkiHi performs all of the medical gas installations in-house. This allows us to maintain strict quality control over this critical building system